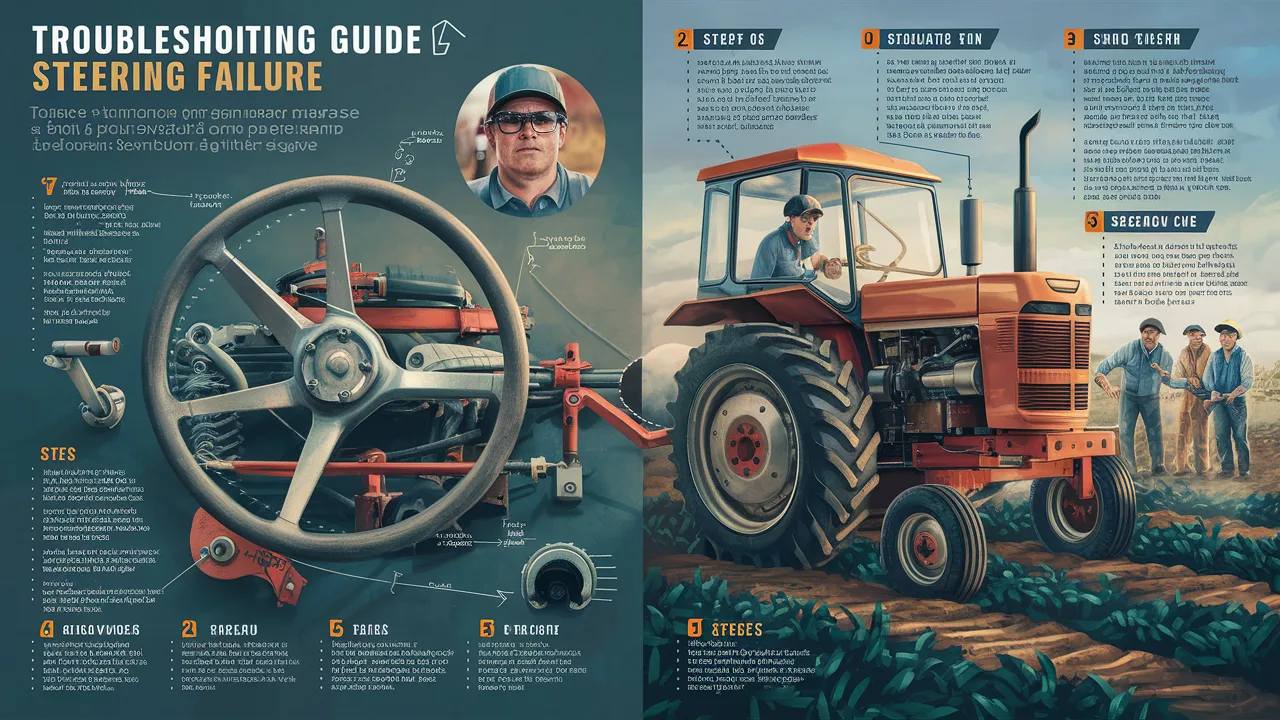

Step-by-Step Troubleshooting Table

| Step | Action | Details | Tools Needed |

|---|---|---|---|

| 1 | Safety First | – Turn off the tractor and remove the key.<br>- Engage the parking brake.<br>- Ensure the tractor is on a flat, stable surface. | Safety gloves, safety glasses |

| 2 | Check for Obstructions | – Inspect the steering mechanism for visible obstructions (e.g., debris, rocks). | Flashlight |

| 3 | Inspect Steering Fluid Level | – Check the steering fluid reservoir for adequate fluid level.<br>- Top up if necessary. | Clean rag, steering fluid |

| 4 | Examine Steering Hoses and Lines | – Look for leaks, cracks, or disconnections in the hydraulic hoses and lines. | Flashlight, clean rag |

| 5 | Check Steering Cylinder | – Inspect the steering cylinder for signs of damage or leakage. | Flashlight |

| 6 | Inspect Steering Pump | – Verify that the steering pump is operating correctly.<br>- Listen for unusual noises. | Basic mechanical tools, stethoscope |

| 7 | Test Steering Linkages | – Check the condition and connection of steering linkages (tie rods, drag links). | Basic mechanical tools |

| 8 | Check Steering Wheel Play | – Turn the steering wheel and check for excessive play or looseness. | None |

| 9 | Inspect Steering Gearbox | – Check the gearbox for proper operation and any signs of wear or damage. | Basic mechanical tools |

| 10 | Check Hydraulic Pressure | – Measure the hydraulic pressure to ensure it is within the specified range. | Hydraulic pressure gauge |

| 11 | Bleed the Hydraulic System | – If air is suspected in the hydraulic system, bleed the system to remove air bubbles. | Wrenches, hydraulic fluid |

| 12 | Check for Mechanical Blockages | – Inspect for any mechanical blockages in the steering mechanism. | Flashlight, basic mechanical tools |

| 13 | Inspect Power Steering Belt | – Check the power steering belt for wear and proper tension. | Belt tension gauge, basic tools |

| 14 | Check for Contaminated Fluid | – Inspect the steering fluid for contamination (e.g., dirt, water). | Clean container, steering fluid |

| 15 | Inspect Steering Knuckles and Joints | – Check steering knuckles and joints for wear or damage. | Basic mechanical tools, flashlight |

| 16 | Lubricate Steering Components | – Lubricate all steering components as per the manufacturer’s guidelines. | Grease gun, appropriate lubricant |

| 17 | Check Steering Sensor (if applicable) | – Inspect electronic steering sensors for proper function (for newer models with electronic steering). | Diagnostic tool, multimeter |

| 18 | Test Steering Performance | – Test the steering by driving the tractor in a safe, open area. | None |

| 19 | Consult the Manual | – Refer to the tractor’s service manual for specific troubleshooting steps and specifications. | Tractor service manual |

| 20 | Seek Professional Help | – If the issue persists, contact a qualified technician for further diagnosis and repair. | Phone, contact information for service |

Additional Tips

- Regular Maintenance: Regularly check and maintain the steering system to prevent failures.

- Record Keeping: Keep a log of all maintenance and repairs for future reference.

- Training: Ensure operators are trained in basic troubleshooting and safe operation practices.

This detailed guide should help diagnose and address steering failures in tractors methodically and safely.

The steering system of a tractor is not merely a mechanical component; it is the linchpin that ensures the safe and efficient operation of this vital piece of agricultural machinery. Imagine navigating through rows of crops or maneuvering in tight spaces without the precision and reliability offered by a properly functioning steering mechanism.

The stakes are high when the ability to steer your tractor swiftly and accurately is compromised. Understanding the underlying intricacies of a tractor’s steering system becomes paramount, especially when faced with unexpected failures that can disrupt daily farm operations.

When confronted with a malfunctioning steering system, farmers, agricultural machinery operators, and mechanics must be equipped with the knowledge to diagnose and address these issues effectively.

From worn-out tie rod ends to hydraulic leaks, the reasons behind steering failures can vary widely but share one common thread — the potential risk they pose to both operator safety and productivity on the farm.

By delving into these challenges head-on and following a systematic approach to troubleshooting, individuals can proactively tackle such setbacks with confidence and precision.

In this detailed guide, we explore the critical components of tractor steering systems, identify telltale signs of impending failure, outline actionable steps for diagnosing mechanical and hydraulic issues, emphasize crucial safety protocols during maintenance procedures, advocate for seeking professional expertise when needed, and underscore preventive maintenance practices aimed at safeguarding against future steering mishaps.

Let us embark on this journey together to ensure that your tractor’s steering remains steadfast in its duty to facilitate secure farm operations.

Understanding Tractor Steering Systems.

Tractor steering systems are integral to the safe and efficient operation of agricultural machinery. A typical tractor steering system consists of essential components such as the steering wheel, hydraulic cylinders, tie rods, and other linkage mechanisms.

The steering wheel is the primary interface through which the operator controls the direction of the tractor. Connected to the steering wheel are hydraulic cylinders that assist in turning the front wheels based on inputs from the driver. Tie rods play a crucial role in transmitting these movements to ensure coordinated steering of the tractor.

Various types of steering systems are commonly employed in agricultural machinery, each with its unique characteristics and benefits. One prevalent type is hydrostatic power steering, which utilizes hydraulic pressure to aid in steering efforts, reducing fatigue for operators during long working hours.

Another widely used system is mechanical-type steering, where physical linkages transfer motion from the steering wheel to the wheels. Electronic power steering has also gained popularity for its precision and responsiveness, relying on sensors and actuators to control steering functions efficiently.

Understanding these diverse tractor steering systems is paramount for operators and mechanics alike to diagnose issues effectively and perform targeted maintenance tasks. By familiarizing oneself with the functions and interplay of these components, individuals can better troubleshoot problems when they arise, ensuring timely repairs and minimizing downtime in agricultural operations.

Signs of Steering Failure.

Recognizing the signs of potential steering issues in a tractor is crucial for ensuring the safety of both operators and equipment. One common symptom indicating steering problems is experiencing difficulty in turning the tractor smoothly.

If you notice that the steering wheel requires excessive effort to turn or feels stiff, it could be a sign of underlying mechanical or hydraulic issues within the steering system. Additionally, if there is noticeable play in the steering wheel, meaning it moves excessively before engaging with the wheels, this could point to wear and tear on components such as tie rods or worn-out steering gear mechanisms.

Promptly addressing any signs of steering failure is paramount to prevent accidents and avoid costly damage to your tractor. Ignoring warning signs like unusual noises when turning, vibrations in the steering wheel, or inconsistent handling can lead to safety hazards in operational settings.

Addressing these symptoms promptly not only ensures the continued functionality of your tractor but also safeguards operators from potential accidents caused by sudden loss of control while operating heavy machinery.

By paying close attention to subtle changes in how your tractor handles—such as drifting to one side while driving, uneven tire wear, or a jerky motion when turning—you can proactively identify and address steering issues before they escalate.

Conducting regular inspections of your tractor’s steering components can help detect problems early on, allowing for timely repairs or replacements to be carried out. Remember that addressing small issues promptly can prevent larger problems down the line and contribute to maintaining a safe operational environment on farms and other agricultural settings.

Troubleshooting Steps for Mechanical Issues.

When faced with steering problems on your tractor, conducting a systematic approach to troubleshooting mechanical issues is crucial. Begin by checking the power steering fluid levels in the reservoir. Low fluid levels can lead to inadequate hydraulic pressure, affecting steering responsiveness.

Use the manufacturer’s guidelines for the type of fluid required and ensure it is at the recommended level before proceeding further. If the fluid is contaminated or has a burnt odor, this could indicate underlying mechanical issues that need closer inspection.

Next, inspect the tie rod ends for any signs of wear or damage. Excessive play in these components can translate into imprecise steering control. To assess their condition, you can perform a visual examination looking for rust, cracks, or looseness. Any compromised tie rod end should be promptly replaced to restore optimal steering function and prevent potential safety hazards while operating the tractor.

If you identify worn out tie rod ends as the culprit behind your steering problems, follow these detailed instructions to replace them effectively:

- 1. Safely elevate the front end of the tractor using appropriate lifting equipment.

- 2. Remove the wheels to access the tie rod ends connected to the steering linkage.

- 3. Unfasten any retaining hardware securing the damaged tie rod ends.

- 4. Disconnect them from both sides of the steering mechanism.

- 5. Install new tie rod ends by reversing these steps, ensuring proper alignment and torque specifications are met.

- 6. Conduct a thorough test drive to confirm that steering performance has been restored.

By meticulously addressing mechanical issues such as low power steering fluid levels or worn out tie rod ends through these troubleshooting steps, operators can enhance safety standards and preserve operational efficiency when utilizing tractors in agricultural settings.

Troubleshooting Hydraulic Steering Problems.

Hydraulic steering systems in tractors can encounter issues that hamper their optimal performance. Common problems include a loss of power assistance, erratic steering behavior, or unusual noises during operation. These issues often stem from air entering the hydraulic lines or leaks compromising the system’s integrity.

Air bubbles can disrupt the smooth flow of hydraulic fluid and cause steering to become stiff or inconsistent. Similarly, leaks in hoses, connectors, or the hydraulic cylinder can lead to a gradual loss of fluid and subsequent steering difficulties. Understanding these root causes is crucial for effective troubleshooting.

To address hydraulic steering problems in tractors, one important step is bleeding air from the system. This process involves removing trapped air bubbles that hinder proper hydraulic function. One method is to turn the steering wheel lock to lock several times while the tractor is stationary, allowing any air to escape through the reservoir filler cap.

Checking for leaks at connection points and along hoses is also essential. A visual inspection coupled with running a gloved hand over potential leak areas can help detect hydraulic fluid seepage that might impact steering responsiveness. Addressing these issues promptly can prevent further damage to the system and ensure safe tractor operations.

By understanding common hydraulic steering issues and following systematic troubleshooting steps such as bleeding air from the system and inspecting for leaks, tractor operators can effectively tackle steering problems before they escalate.

Practicing regular maintenance routines like checking fluid levels and examining hoses for wear can aid in early issue detection and prevent unexpected breakdowns during crucial farming tasks. Prioritizing proactive hydraulic system care not only enhances equipment longevity but also safeguards operator safety by maintaining reliable steering functionality on tractors used in demanding agricultural environments.

Safety Precautions When Dealing with Steering Repairs.

When it comes to addressing steering issues on a tractor, prioritizing safety measures is paramount to prevent accidents and ensure the well-being of the operator. Before attempting any maintenance or repairs on the steering system, it is crucial to disconnect all power sources to avoid unintended movements that could result in injuries or damages to the equipment. This step applies whether working on mechanical components like tie rods or hydraulic elements such as cylinders.

Using appropriate tools and personal protective equipment (PPE) is essential when conducting repairs on a tractor’s steering system. For instance, when working on hydraulic components, wearing gloves and safety goggles can shield against potential fluid leaks or splatters that may cause skin irritation or eye injuries. Additionally, utilizing specialized tools designed for specific tasks can enhance efficiency while reducing the risk of accidents during maintenance procedures related to the steering mechanism.

By adhering to proper safety protocols such as disconnecting power sources and employing suitable tools and PPE, operators and mechanics can create a safer work environment when troubleshooting steering problems on tractors.

These precautions not only mitigate risks associated with handling heavy machinery but also contribute to ensuring effective and secure repairs without compromising on personal safety. Prioritizing safety measures while dealing with steering repairs underscores the importance of practicing caution and diligence in agricultural machinery maintenance practices.

Consulting a Professional Mechanic.

In cases where the troubleshooting steps outlined earlier do not resolve the steering issues with your tractor, it is advisable to seek assistance from qualified mechanics specializing in agricultural machinery. Professional mechanics possess the expertise and diagnostic tools needed to identify complex mechanical or hydraulic problems that may be beyond the scope of routine maintenance.

When selecting a mechanic or service center, consider factors such as their experience working on tractors, reputation for quality repairs, and access to genuine replacement parts specific to your tractor’s make and model.

For example, let’s say you have followed all the recommended troubleshooting steps but still experience erratic steering behavior in your tractor. Consulting a seasoned mechanic who has dealt with similar issues before can offer valuable insights into the root cause of the problem.

A skilled mechanic will conduct thorough diagnostics to pinpoint the exact issue, whether it involves recalibrating hydraulic systems or replacing worn-out mechanical components. By entrusting your tractor to capable hands, you not only ensure accurate repairs but also prevent potential safety hazards associated with faulty steering systems.

When choosing a mechanic specialized in agricultural machinery repairs, look for certifications or affiliations with reputable organizations within the industry. For instance, a mechanic certified by the Agricultural Industry Electronics Foundation (AEF) demonstrates competence in handling precision farming equipment like advanced steer-by-wire systems found in modern tractors.

Furthermore, inquire about warranties provided on repair services and parts used during maintenance procedures to guarantee long-lasting solutions for your tractor’s steering concerns. By partnering with a skilled professional well-versed in agricultural equipment repairs, you enhance operational efficiency on your farm while prioritizing safety through reliable steering system maintenance.

Preventative maintenance practices.

Preventative maintenance practices play a crucial role in ensuring the reliability and longevity of a tractor’s steering system. Regular greasing of moving parts, such as ball joints and steering linkages, can help reduce wear and tear that may lead to steering failures over time.

By creating a lubricated barrier between metal components, greasing minimizes friction and prevents premature damage that could compromise the efficiency of the steering mechanism. For instance, using a high-quality lithium-based grease on pivot points can enhance the smooth operation of the steering system and prolong its lifespan.

In addition to greasing key components, it is essential to conduct thorough inspections of hoses and fittings regularly to identify any signs of wear, leaks, or damage. Inspecting hydraulic lines for cracks or abrasions and checking for loose connections can prevent potential fluid leaks that might affect the overall performance of the steering system.

By adhering to a proactive maintenance schedule that includes visual checks and testing for hydraulic system integrity, operators can address minor issues before they escalate into major problems. For example, monitoring hose conditions for bulges or soft spots can indicate weaknesses that require immediate attention to avoid sudden failures during operation.

Scheduling routine maintenance.

Scheduling routine maintenance inspections at recommended intervals is paramount in preventing unexpected steering failures that could jeopardize both operator safety and agricultural productivity. Aligning maintenance tasks with manufacturer guidelines ensures that critical systems are monitored systematically, reducing the chances of unforeseen breakdowns.

By creating a checklist for regular service intervals focused on the steering system—such as inspecting tie rods for excessive play or checking power steering pump functionality—operators can proactively maintain their equipment in top condition.

Implementing these preventative measures not only safeguards against costly repairs but also promotes uninterrupted farm operations by mitigating the risks associated with steering malfunctions.

Conclusion: Ensuring Safe Tractor Operations.

In conclusion, a tractor’s steering system is a critical component that directly impacts the safety of farm operations and the well-being of operators. By understanding the components of a tractor’s steering system, recognizing signs of failure, and following the troubleshooting steps outlined in this guide, farmers, agricultural machinery operators, and mechanics can effectively address steering issues promptly.

Regular maintenance and proactive troubleshooting are key to preventing accidents and ensuring the efficient functioning of tractors in the field.

By recapitulating the importance of maintaining a properly functioning tractor’s steering system, we underscore that prioritizing safety is paramount. Efficient farm operations hinge on reliable equipment, and operator well-being depends on functional steering mechanisms.

As such, adhering to recommended maintenance practices, promptly addressing any signs of steering failure, and seeking professional assistance when needed are all integral to guaranteeing safe tractor operations. Remember, a well-maintained steering system is not just a matter of convenience but a fundamental aspect of operational safety in agricultural settings.